Capacitors are fundamental components in electronic circuits, serving roles that range from energy storage to filtering voltage fluctuations. Over time, capacitors can degrade or fail, impacting the performance of the devices they support. Learning how to test a capacitor can save you time, money, and frustration by helping you identify faulty components before they cause larger problems. Origin Data Global Limited (ODG) provides insights into the testing process, ensuring both safety and accuracy.

Understanding Capacitors and Their Importance

A capacitor is essentially an electronic component that stores and releases electrical energy. It consists of two conductive plates separated by an insulating material called a dielectric. Depending on the type and application, capacitors may vary in size, shape, and capacitance value.

In practical terms, capacitors are used in:

- Power supply circuits to smooth voltage variations

- Timing circuits to regulate signal frequency

- Filtering applications to eliminate noise

- Energy storage for flash photography or backup systems

A malfunctioning capacitor can lead to device failure, flickering lights, or even damage to other components. Knowing how to test a capacitor ensures that you can maintain electronics in optimal condition.

Tools Needed for Testing

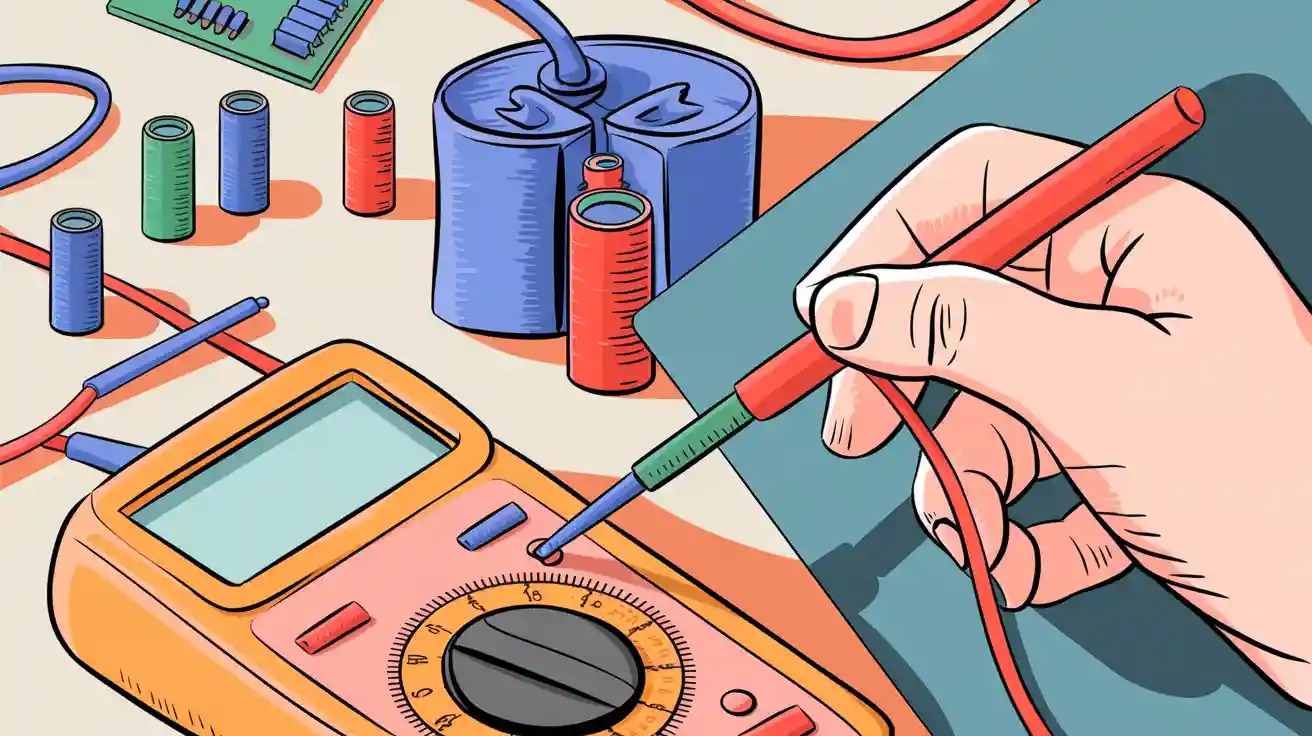

Testing a capacitor doesn’t require advanced equipment. The primary tool is a multimeter, which can measure capacitance, resistance, and voltage. A digital multimeter with a capacitance setting is ideal for accurate readings.

Other recommended items include:

- Insulated gloves for safety

- Screwdrivers or tools to safely remove the capacitor from the circuit

- A resistor for discharging high-voltage capacitors

Safety is critical, especially when dealing with capacitors that store significant charge. Always ensure power is disconnected before testing.

Preparing the Capacitor for Testing

Before connecting a multimeter, it is essential to prepare the capacitor properly. Follow these steps:

- Disconnect Power: Ensure the device or circuit containing the capacitor is completely powered off.

- Discharge the Capacitor: Use a resistor or a dedicated discharge tool to release stored energy safely. Touching a charged capacitor directly can cause shocks or damage to the multimeter.

- Remove the Capacitor (if necessary): For accurate readings, especially in complex circuits, it is often best to remove the capacitor from the circuit.

This preparation ensures safety and prevents inaccurate readings caused by surrounding circuit elements.

Step-by-Step Guide on How to Test a Capacitor

Testing a capacitor is straightforward if approached methodically. Here’s how:

1. Set the Multimeter Correctly

Turn your multimeter to the capacitance measurement mode. This setting is often marked with a symbol similar to “—|(|—.” If your multimeter lacks a capacitance mode, you can measure resistance as a workaround, but capacitance mode provides the most direct and reliable reading.

2. Connect the Probes

Attach the multimeter probes to the capacitor terminals. Polarity matters for electrolytic capacitors, where the positive and negative leads must match the multimeter probes. For non-polarized capacitors, the orientation does not matter.

3. Read the Value

Observe the reading on the multimeter display. The value should closely match the capacitance rating printed on the capacitor. Small deviations are normal due to tolerances, but significant differences indicate a faulty capacitor.

4. Compare with Specifications

Cross-check the measured value with the capacitor’s rated capacitance. If the measured value is lower, higher, or fluctuates significantly, the capacitor may be failing or already damaged.

5. Advanced Checks (Optional)

For those with more experience, additional tests can include:

- ESR (Equivalent Series Resistance) Testing: Measures the internal resistance that affects performance in high-frequency circuits.

- Leakage Current Testing: Detects if the capacitor is allowing current to pass through when it should not.

These advanced tests help pinpoint subtle failures that simple capacitance measurements might miss.

Common Issues Identified by Testing

By regularly testing capacitors, you can detect several common problems:

- Short Circuits: The capacitor allows current to pass freely, causing potential damage.

- Open Circuits: The capacitor does not charge, resulting in a circuit malfunction.

- Leakage or Reduced Capacitance: Over time, the dielectric material can degrade, lowering efficiency.

Recognizing these issues early can prevent larger electronic failures and save both time and money.

Choosing Quality Capacitors

While testing helps maintain circuits, starting with high-quality capacitors reduces the likelihood of frequent failures. ODG emphasizes sourcing reliable components from reputable suppliers. Origin Data Global Limited (ODG) offers an extensive range of electronic parts, including hard-to-find and end-of-life capacitors, ensuring quality through rigorous QA and QC protocols.

ODG is a trusted member of industry organizations such as ERAI, and holds certifications like ISO9001, ISO14001, AS9120B, and ESD compliance, reflecting its commitment to excellence. Partnering with knowledgeable staff allows customers to access tailored solutions and fast, dependable delivery.

Safety Considerations

Safety cannot be overstated when testing capacitors. Some key precautions include:

- Never test a capacitor while it is connected to a live circuit.

- Always discharge high-voltage capacitors using a resistor.

- Avoid touching terminals directly, especially with bare hands.

- Use protective eyewear to prevent injury from accidental capacitor bursts.

Following these guidelines ensures a safe testing environment and accurate results.

Practical Applications of Testing Capacitors

Knowing how to test a capacitor benefits a wide range of scenarios:

- Home Repairs: Fixing appliances like microwaves, TVs, or power supplies.

- Electronics Hobbies: Maintaining DIY projects or robotics circuits.

- Industrial Maintenance: Ensuring machinery and production equipment function reliably.

Regular capacitor testing can extend the life of devices and prevent unexpected downtime.

ODG’s Role in Electronic Component Sourcing

ODG combines industry expertise with an extensive distribution network to provide customers with high-quality components. For anyone interested in capacitor testing, having access to reliable capacitors is crucial. ODG’s stores feature millions of parts catering to global OEMs, backed by a professional team that understands specific technical needs.

Through tailored sourcing, rigorous quality assurance, and fast delivery, ODG helps electronics professionals maintain and repair devices efficiently, reducing delays caused by component shortages.

Follow ODG:

YouTube: https://www.youtube.com/@Origin_Data Facebook: https://www.facebook.com/OriginDataGlobalLimited Twitter: https://twitter.com/Origin_IC Tiktok:

https://www.tiktok.com/@origin_data Szxlxc:

https://www.szxlxc.com