Introduction

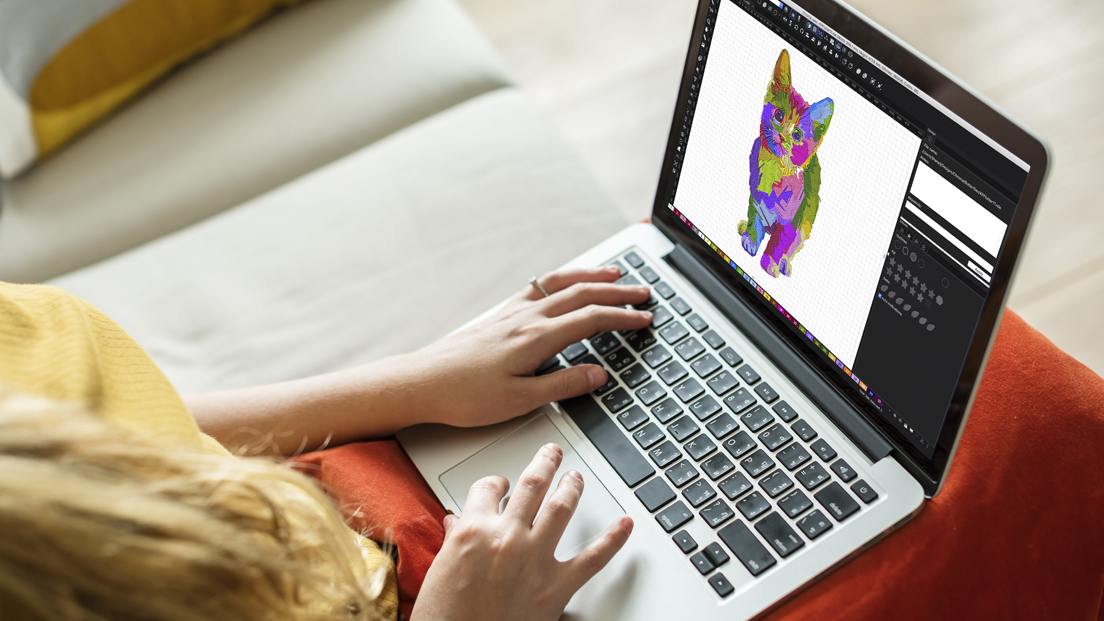

Imagine a stunning logo on a screen and its perfect replica, stitched in thread on a baseball cap. The bridge between these two realities isn’t magic—it’s a skilled craftsperson known as a digitizer. In the world of machine embroidery, digitizers for embroidery are the essential translators, turning digital artwork into a language of stitches that machines can understand. Whether you’re a hobbyist frustrated by auto-digitized results or a business owner seeking consistent quality, understanding this role is crucial. This guide demystifies the entire field, from the core skills a digitizer needs to the tools they use. We’ll explore what makes a great digitizer, how the process works, and provide a clear path for both those looking to hire one and those aspiring to become one.

What is an Embroidery Digitizer? More Than Just a Converter

An embroidery digitizer is not a software program or a simple file converter. They are a hybrid professional—part graphic artist, part engineer, and part fabric scientist. Their primary job is to take static artwork (like a JPG, PNG, or AI file) and create a programmed embroidery file (like DST, PES, or EXP).

But this process, called digitizing, is far from automated. Think of the original artwork as a photograph of a finished cake. The digitizer is the pastry chef who writes the recipe. They decide the ingredients (stitch types), the order of steps (stitch sequence), and how to adjust for the oven’s quirks (fabric behavior). A true digitizer uses specialized software to manually plot stitch paths, assign stitch types, and input commands that control the embroidery machine’s every move. The quality of their “recipe” directly determines if the final stitched design is a professional masterpiece or a puckered, thread-broken mess.

The Core Skills of a Professional Digitizer

What separates a professional from an amateur with software? It’s a specific blend of hard and soft skills:

- Technical Proficiency: Mastery of professional digitizing software (like Wilcom, Hatch, or Pulse) is the baseline. This goes far beyond knowing which buttons to click.

- Artistic Eye & Understanding of Design: They must understand composition, color theory, and how to simplify or enhance artwork for the medium of thread. Not every detail in a complex illustration will stitch well.

- Mechanical Knowledge of Embroidery Machines: They know how a machine operates—how the needle penetrates, how the hoop moves, how thread tension works. They design files that run smoothly on physical equipment.

- Material Science: A great digitizer knows that a design for a stiff canvas hat needs different settings than the same design for a stretchy athletic jersey. They understand how different fabrics, stabilizers, and threads interact.

- Problem-Solving & Patience: Digitizing is iterative. It involves testing, identifying issues (like puckering or registration errors), and methodically tweaking the digital file to solve them.

The Step-by-Step Digitizing Process Explained

To appreciate the value a digitizer brings, it helps to understand their workflow. Here’s what happens when they transform your artwork:

- Artwork Analysis & Preparation: The digitizer examines the source file for challenges—tiny text, gradients, ultra-fine lines. They may suggest simplifications to ensure a stitchable outcome.

- Setting the Underlay: This is the critical, invisible foundation. The digitizer creates a layer of stitches that stabilizes the fabric, prevents puckering, and provides a base for the top stitches. Skipping this is the #1 cause of amateur results.

- Defining Objects & Assigning Stitch Types: The design is broken into elements (objects). For each, the digitizer assigns the best stitch type: Satin Stitch for glossy borders and text, Fill Stitch for solid areas, or Run Stitch for fine details.

- Setting Parameters: This is where precision happens. The digitizer sets the stitch density (too loose shows fabric; too tight is stiff), direction (which affects texture and light reflection), and pull compensation (digitally adjusting shapes to counteract fabric distortion during sewing).

- Creating the Sequence & Adding Commands: They determine the sewing order (typically background to foreground) and insert machine commands for trims and jumps between sections and color changes.

- Simulation & Testing: Using software simulation, they watch a virtual stitch-out. The best digitizers often stitch a physical sample, especially for crucial jobs, to ensure perfection before delivery.

Tools of the Trade: Software & Hardware

Digitizers for embroidery rely on specialized tools:

- Professional Software:

- Wilcom EmbroideryStudio: The industry standard for professionals, known for its powerful tools and precision.

- Hatch Embroidery: A very popular, user-friendly choice with tiered pricing, excellent for beginners moving into professional work.

- Pulse Ambassador: Another high-end suite favored by many corporate and high-volume digitizers.

- Hardware: A powerful computer with a good graphics card and multiple monitors is standard. A dedicated embroidery machine for testing is a hallmark of a serious professional.

For Beginners: How to Start Learning Digitizing

If you’re inspired to become a digitizer, here’s a practical path:

- Start with the Right Mindset: Understand it’s a skilled trade that takes time to learn. Patience is key.

- Invest in Entry-Level Software: Begin with a program like Hatch Embroidery (which has a free trial and affordable tiers). Its learning resources are superb. Avoid “auto-digitize” buttons as a crutch.

- Devour Educational Resources: Utilize software maker tutorials, YouTube channels from established digitizers, and online courses. Practice relentlessly with simple designs.

- Learn the “Why,” Not Just the “How”: Don’t just memorize steps. Understand why you use a certain underlay on knit fabric or how pull compensation fixes a distorted shape.

- Build a Portfolio: Digitize free designs for friends or create personal projects. Document your progress with photos of your stitch-outs.

For Professionals & Businesses: How to Hire a Great Digitizer

When your business needs quality digitizing, knowing how to choose is vital:

- Evaluate Their Portfolio Critically: Look for photos of actual stitch-outs, not just screen images. Check for clean finishes, smooth satin stitches, and flat fill areas on various fabrics.

- Assess Their Communication: A good digitizer will ask questions—about your fabric, garment type, and intended use. If they don’t ask, they’re not optimizing for your needs.

- Understand Pricing Structure: Prices are typically based on stitch count and complexity. Be wary of prices that seem too good to be true; you often pay for quality.

- Check Their Revision Policy: A professional will offer 1-2 free revisions, understanding that a test stitch might reveal a needed tweak. This shows they stand behind their work.

- Request a Test Project: For a long-term partnership, give them a sample design. Evaluate not just the final file, but the ease of the process and their responsiveness.

The Future of Digitizing: AI and Automation

The field is evolving. AI-assisted tools are emerging that can automate initial tracing or suggest stitch types. However, these are aids, not replacements. The artistic judgment, material knowledge, and problem-solving skills of a human digitizer remain irreplaceable for achieving truly premium, reliable results. The future digitizer will use AI as a powerful assistant to increase efficiency, not as a substitute for expertise.

Conclusion

Digitizers for embroidery are the unsung architects of the stitched world. They possess a unique alchemy of artistic vision and technical rigor, transforming flat images into dynamic, tactile creations. Whether you are embarking on the rewarding journey to become one or seeking to partner with one for your business, understanding the depth of this craft is the first step. For the aspiring digitizer, embrace the learning curve with patience. For the business owner, view a skilled digitizer not as a cost, but as a strategic partner in quality. In every precise, durable, and beautiful embroidered piece, you see the invisible handiwork of the digitizer—the essential bridge between idea and thread.